News Releases

Farmers are spending more and more time planning, organising and documenting their work. FendtONE offboard is a digital solution for simple, operation-specific work organisation and documentation and complements the FendtONE onboard driver workstation. FendtONE offboard will now be rolled out and new functionality will be added continuously based on current and future customer needs.

Agricultural farms are all set up slightly differently. The result: different challenges and cost drivers. While smaller farms may need to spend more time on job planning and documentation, a farm with many employees may spend more time on labour planning. In times of skill shortages, legal restrictions and tight harvest windows, farmers need to use their time as efficiently as possible.

Rising costs for fuel, fertilisers and chemicals as well as labour are a burden on farms worldwide. On average, 45 percent of the working time on an arable farm is spent being productive in a machine and 15 percent is spent on machine maintenance and care (source: Betriebsdatenauswertung BB Göttingen). This results in 60 per cent of the working time for machine-related work.

The remaining 40 per cent of the working time is mainly taken up by organisational activities such as managing the land, planning jobs with machines, labour deployment, and job documentation. This is exactly where FendtONE offboard provides support and can reduce the amount of time spent on these tasks with simple solutions.

Precise preparation saves time

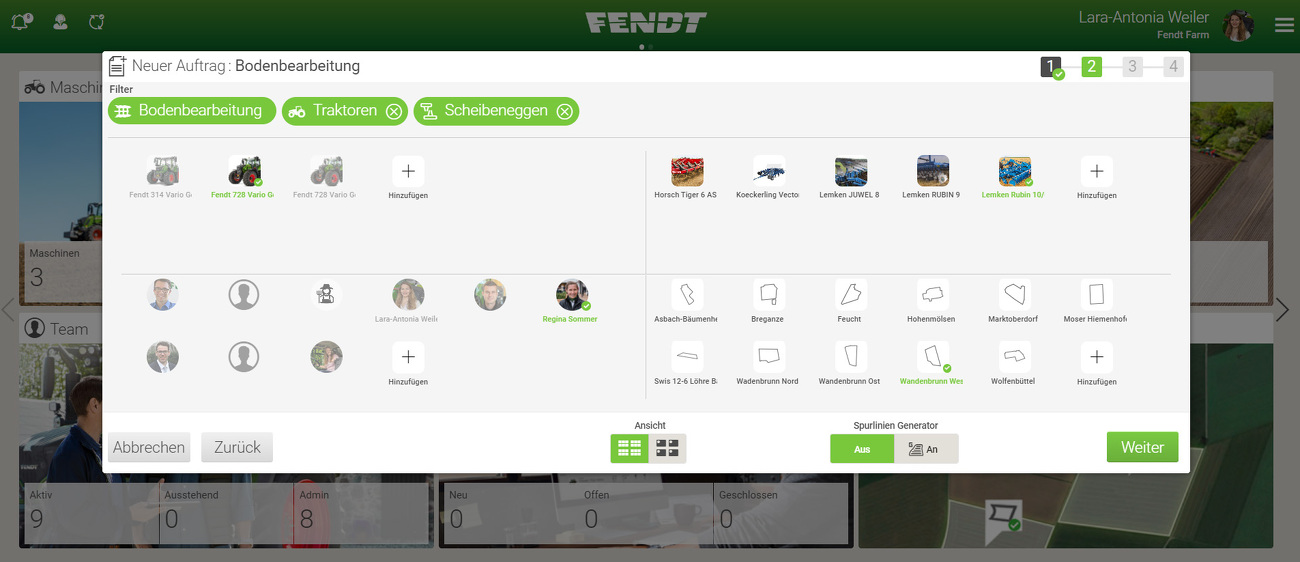

When the time is right, farmers need to be maximising available weather windows. Lengthy preparation time costs valuable time that would be better spent in the field. With FendtONE all resources can be created before the season begins, making job creation during the season much quicker. The "Team" area records all employees on the farm. There, each person can be assigned a specific role. While permanent employees can create jobs, for example, this is not the case for temporary workers or trainees. Tractors, implements and self-propelled machines are clearly stored with their data in the "Machines" area. Farm supplies such as fertiliser and chemicals can be planned in advance. This preparation facilitates the assignment of jobs and saves time at the start of the season.

Field boundaries and waylines lines can also be stored ready to be sent to the required machine in moments, ensuring maximum performance of the combination from the very first momoent in the field. These boundaries and waylines can be checked in advance in FendtONE offboard and then sent directly to the machine via mobile radio. In this way, the fields are processed precisely and efficiently on the basis of uniform master data, regardless of the machine. If farmers use smart technologies such as the Fendt Guide, Section Control (SC) or Variable Rate Control (VRC), this simultaneously reduces the consumption of farm resources and increases economic efficiency. These solutions come into their own in fields with non-uniform boundaries and soil conditions, ensuring no product is wasted.

Reduction of downtimes and machine optimisation in the field

Harvest chains work effectively when they run without interruptions. Downtime due to insufficient fuel or lack of knowledge of the local area are avoidable with FendtONE. Farms with widely scattered or changing fields as well as many machines or even changing drivers benefit from the "Map+" function. The map shows the position of the machines and the fuel or AdBlue level in real time, provided the tractor has Fendt's basic telemetry package. Machines in the field can then be kept supplied with products such as fertiliser and diesel quickly and efficiently, even if the delivery driver isn't certain where the machine is. The result: downtimes are reduced.

Smart technology such as autosteering, Section Control and Variable Rate Control in FendtONE onboard make efficient use of resources, significantly reduce the consumption of farming resources and can thus help to increase the profitability of a farm.

Jobs directly from the office to the machine

Currently, most companies organise work jobs by paper, phone or via chat programs. With FendtONE offboard, work orders can be planned the evening before in just a few clicks using the "Fendt Task Doc: Create Job" function and sent directly to the machine. At the beginning of the working day, all information such as the machine and implement, the area to be worked and the exact work order are stored on the machine. There is no need for personal or telephone coordination and drivers can start work straight away. Another advantage: all information is visible at a glance and the machines are optimally utilised.

As soon as the job is completed, it is sent from the machine back to the office and appears there in the "Fendt Task Doc: Job Reports" area. The report is saved and can be exported for documentation at a later date if required.

Documentation simple and fast

The social and legal demands for careful use of resources and conservation of the soil are growing. Parallel to this, the scope and demand for documentation of work carried out as well as fertilisation and plant protection measures is also growing. This often takes place at the end or after the season. The job reports in FendtONE offboard automatically contain essential information on each field, such as the fields worked or the application rate applied. The saved job reports can be saved, but also exported as a PDF. This information facilitates documentation in accordance with applicable legal requirements and significantly reduces the time required to record this work. Farms without a farm management system can easily and intuitively enter into digital documentation with FendtONE. Companies with an existing system can supplement this with FendtONE offboard, an easy-to-use solution.

Future-proof, with room to grow

FendtONE already records numerous amounts machine data and makes it visible to farmers. In this way, farmers can use this as a basis for operational decisions and optimise their resources on a farm-by-farm basis. FendtONE offboard is being further developed constantly. With new technologies and machines, this platform will expand in terms of functionality and offer new features in order to provide customers with modern, efficient solutions in the future.