News Releases

Until now, round bales were billed according to their type, size and number. In combination with a load-sensing or TIM-capable tractor, new functions for the Fendt Rotana round balers now allow analysis by weight and moisture. In addition, some processes have been automated. Automatic bearing lubrication is now available for the variable chamber round balers.

Fendt Loadsensing-Pro functions or Fendt TIM-Pro functions are now optionally available for the Fendt Rotana Xtra round baler models. The new function package can be selected depending on the equipment of the tractor.

These new options include the following applications:

- Moisture analysis

- Automated stopping after binding (only with Tractor Implement Management System, TIM)

- Weighing function

- Automation of the bale ejection process

- Automatic cleaning of the knife slots

- LED maintenance lighting

- Function to strengthen the bale edge layer

Exact recording of weight and moisture

Accurate data on bale weight and moisture are important parameters for evaluating forage quality and for billing in contract work. The Fendt Rotana collects this information via sensors and stores it field-specifically in Fendt Task Doc. All data is stored in ISO XML format and can thus be used across mixed fleets.

The Fendt Rotana is the first round baler on the market with a reliable and calibration-free bale weighing system. Three weighing cells on the machine determine the exact weight of the pressed bale. During the weighing process, the pick-up is automatically lifted so that its supported dead weight does not influence the measurement. To avoid incorrect measurements in cropped terrain, the machine compares the total weight of the round baler before and after bale ejection. The calculated difference corresponds to the bale weight and factors such as a subsequently inserted netting roll have no influence on the measurement result. Repeated calibration of the weighing cells is not necessary.

Two sensors on the inner wall of the bale chamber permanently measure the moisture of the baled material during baling. This is associated with a moisture alarm in the terminal. This warns when an individually adjustable moisture limit is exceeded. Baling at too high moisture is avoided. This significantly reduces the risk of hay and straw bales spoiling whilst in storage. In addition, bales baled on field areas with higher moisture can be separated and stored later. This allows for additional post-drying.

From the combination of bale weight and moisture, the actual-harvested dry matter per area can be determined. Subsequently, the use of fertilisers can be optimised based on this knowledge. This is essential for the economic and sustainable management of farmland today. Rising costs for fertilisers, strict regulations, cost pressure and the special location of many permanent grassland areas close to waterways are forcing the importance of needs-based fertilisation.

Automated bale ejection

With the new Auto Tailgate function, the Fendt Rotana opens the tailgate automatically immediately after binding. When the bale leaves the chamber, the tailgate closes as quickly as possible. This reduces friction on the chamber wall and thus unnecessary crumbling losses, saves time and relieves stress on the driver, helping to improve driver efficiency.

For TIM-capable tractors, the TIM Auto Stop function is also available. This stops the tractor automatically as soon as the bale is wrapped. Afterwards, activating the joystick is enough to start driving again.

During the net binding process, automated cleaning of the knife slots takes place. The swing-out blades are automatically swung in and out again to keep the slots clean. Thanks to the automated cleaning system, the combination is immediately ready for use when changing from uncut hay or straw bales to silage bales. The time-consuming change to blind knives is no longer necessary, helping to reduce downtime.

Firmly baled

Short-cut straw is increasingly used as bedding or for energy production, but this can lead to unstable bales. For this special application, the Fendt Rotana offers the edge layer optimisation function. In this process, the majority of the bale is cut very short and finalised with a layer thickness of uncut pressed material. The thickness of the edge layer can be individually adjusted via the terminal. This increases the stability of each baler against external influences such as storage and transport.

Optimum maintenance even in poor lighting conditions

A pack of LED maintenance lights illuminates the area under the side panels and maintenance work can be carried out directly in the field, even on long working days.

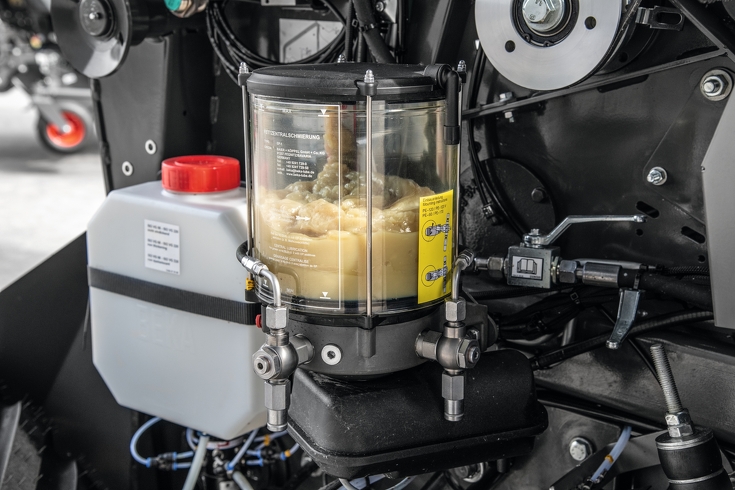

Automatic bearing lubrication for the variable presses

Fendt was the first manufacturer on the market to develop automatic bearing lubrication specifically for all variable chamber Fendt round balers. The unique design also reaches the moving swing rollers inside the bale chamber. A specially designed tunnel guides the lubrication lines safely and securely to the hard-to-reach rollers and effectively protects the lines from fatigue. Automatic lubrication reduces the maintenance time and significantly increases the service life of the roller bearings.

The new Pro functions for the Fendt Rotana round balers can be ordered from July 2022 and will be delivery to customers will start in the autumn.